Application Scenarios

At a major ethylene cracker plant in South Korea, precise temperature control of pyrolysis furnaces was compromised by aging analog output cards that suffered from drift and intermittent channel failures. After upgrading to the ABB PFEA111-20 3BSE028140R0020. operators observed immediate improvements: furnace outlet temperatures stabilized within ±1°C of setpoint, and unscheduled shutdowns due to control valve mispositioning ceased entirely. The module’s per-channel open-circuit detection alerted maintenance teams to a failing positioner on Channel 5 before it caused a trip—demonstrating how the ABB PFEA111-20 3BSE028140R0020 transforms passive output into intelligent, self-aware control infrastructure.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Channel-Level Isolation & Diagnostics

Each of the 8 outputs in the ABB PFEA111-20 3BSE028140R0020 features independent galvanic isolation and real-time fault monitoring. Unlike legacy modules that report only “module OK/NOK,” this unit pinpoints which channel failed and why—cutting troubleshooting time from hours to minutes.

Innovation Point 2: Native HART Transparency Without Extra Hardware

The module allows HART digital signals to ride atop 4–20 mA outputs without requiring external multiplexers. This enables asset management systems like AMS Device Manager to communicate directly with smart valve positioners during normal operation—unlocking predictive maintenance capabilities.

Innovation Point 3: Software-Configurable Output Ranges

Engineers can assign 4–20 mA to Channels 1–4 and 0–10 V to Channels 5–8—all within Control Builder M. This flexibility eliminates the need for multiple module types in mixed-signal applications like HVAC or lab automation.

Innovation Point 4: Sub-Millisecond Update Rate for Fast Control Loops

With an output refresh cycle under 1 ms, the ABB PFEA111-20 3BSE028140R0020 supports high-dynamic applications such as compressor surge control or reactor pH regulation, where timing precision directly impacts safety and yield.

Application Cases and Industry Value

In a greenfield LNG liquefaction project in Qatar, the ABB PFEA111-20 3BSE028140R0020 was deployed across 12 refrigerant compressor trains to modulate anti-surge valves and guide vanes. During commissioning, engineers used its HART pass-through feature to calibrate Emerson FIELDVUE positioners remotely—avoiding scaffolding costs and confined-space entries. Over two years of operation, zero AO-related trips were recorded. Plant reliability engineers credited the module’s stable output and diagnostic clarity as key enablers of 99.8% operational availability. The ABB PFEA111-20 3BSE028140R0020 proved that even “simple” output modules can be strategic assets in mega-projects.

Related Product Combination Solutions

ABB PFEA112-65 3BSE030369R0065: 16-channel AO counterpart for higher-density applications

ABB PFES111 3BSE028138R0011: 8-channel analog input (AI) module—ideal for closed-loop pairing with ABB PFEA111-20 3BSE028140R0020

ABB TB850 Baseplate: Required mounting platform for S800 I/O modules in redundant AC 800M systems

ABB CI854A (07KT98C): Profibus DP communication module to connect third-party remote I/O when expanding beyond S800

ABB Control Builder M: Engineering tool for configuring channel parameters, HART settings, and alarm thresholds

ABB TU830/TU831: Terminal units for field wiring—compatible with spring-clamp or screw terminals

ABB 3BSE042287R1 (S800 I/O Redundancy Kit): Enables dual-module hot standby for critical AO loops

ABB System 800xA Asset Optimization: Software suite that leverages HART data from ABB PFEA111-20 3BSE028140R0020 for valve health analytics

Installation, Maintenance, and Full-Cycle Support

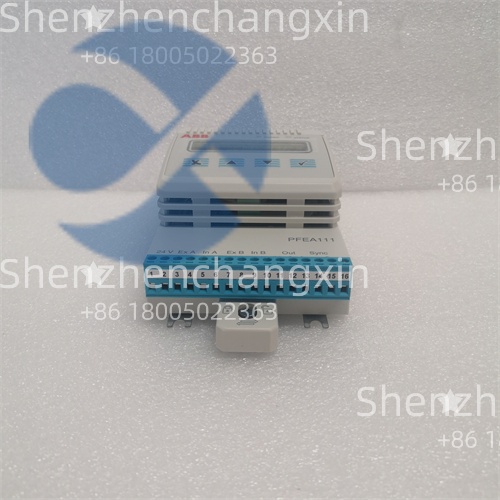

Installation of the ABB PFEA111-20 3BSE028140R0020 follows standard S800 practices: mount onto a compatible TB8xx baseplate, secure with the locking lever, and connect field wiring via TU830/TU831 terminal blocks. No jumpers or DIP switches are needed—every parameter (range, engineering unit, HART enable) is configured in Control Builder M and downloaded to the module. For HART-enabled loops, ensure shielded twisted-pair cables with single-point grounding to preserve signal integrity.

During operation, the module continuously monitors its own health and reports status via the S800 bus. Maintenance teams can view channel-specific diagnostics in System 800xA faceplates or export event logs for trend analysis. In case of failure, the unit supports hot swapping in non-redundant systems (with proper configuration), minimizing process disruption.

We validate every ABB PFEA111-20 3BSE028140R0020 through rigorous functional testing—including full-scale output sweep, HART communication handshake, open-circuit simulation, and thermal stress cycling. All units ship with test certificates and firmware version documentation. Our technical team provides pre-sales compatibility checks, post-delivery configuration support, and lifecycle management guidance—including migration paths to next-gen I/O platforms.

Contact us for a customized solution—whether you need a single replacement module, a bulk order for a brownfield upgrade, or expert advice on optimizing your S800 I/O architecture.